- Details

- Written by: P. St.Marie

- Category: Firearms Tech.

- Hits: 13615

This was written for Swiss rifles, but it applies to all rifles including the ARs.

We manufacture brakes. (Note: We don't sell to the public, only through our distributors)

This is a threading kit with pilot.

This is a threaded brake, intended to reduce felt recoil.

Note the thickness of the Brake wall.

This is a Clamp On Brake designed with the same intent.

Installed

This is a threaded Damper, or Compensator for reducing group size. This unit is rifle, caliber, barrel length, ROT and projectile weight specific, that being 175gr.

Installed

This is a flash suppressor. A Brennan Nil-Flash that shows zero signature on ar15 type rifles.

We did the prototype testing on this brake in Lost Prairie during the early 90's. It produce a zero flash signature.

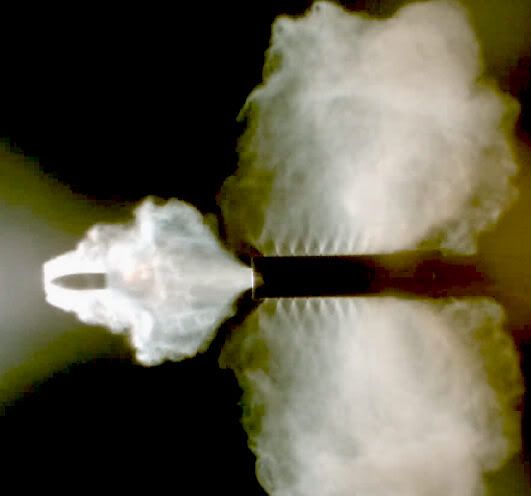

This is an effective Flash Suppressor showing dispersion and lack of actual flash.

They're not a brake, and a flash suppressor (combo) is never an efficient brake.

4 years of field testing our own products before production and distribution has proven this over and over ad nauseum.

The chances of any brake reducing group sizes is low and purely co-incidental, however, we have had a few reports of the threaded brake making a difference. This is an involved subject and I'd post it if requested, otherwise what I've given you is based on a very long history of manufacturing, R&D and field testing on both Brakes and Dampers.

Essentially, a true, effective Brake must be thick walled right out of the gate. The rearward angle of the ports must have sufficient surface upon which the gases can act. Without that angle and thickness you'd have no forward push on the rifle. Look closely at your zfk55 or AMT, and you'll understand.

Bear in mind that for any Brake to work effectivley, the center must be concentric to the rifle's bore. Any deviation from concentricity will affect POI. This is especially important for Dampers (Compensators).

The truth of this statement is proven in our field tests with both threaded and clamp-on Brakes.

If the unit is to be threaded, the threader itself must have a bore pilot supplied for the threading operation. Without a pilot there can only be threading pertinent to the OD of the barrel. A pilot determines threading based on the ID of the barrel. That being the case, a clamp-on type brake centers itself based on the OD, and the Brake's opening must then be larger than that of the Threaded Brake to allow for the passing of gases without destablilizing the passing projectile.

Center concentricity is essential to maintain equal gas release around the base of the projectile. If a clamp-on brake is perfectly aligned in this manner, rest assured it's pure luck for that particular barrel/brake combination.

P. St.Marie

Show 'em Off!

Add your rifle to the AR-10 Photo Thread!

All content of this site is copyright 2003 - 2017

AR-10(T)™, AR-10™, are trademarks of ArmaLite, Inc.®

AR10T.com is NOT endorsed or affiliated with ArmaLite, Inc.®